Case Study

Taiwan’s powerhouse for green energy

The development of green energy industries is already a global trend. Taiwan has always been an important supplier for technological industries around the world, but Taiwan also almost entirely depends on imports for many key materials. This has resulted in low gross profits over a long period of time.

Inside the Hi-GEM Research Center of NCKU, a group of diligent academics are searching for a new future for Taiwan’s green energy technology through multidimensional applications of materials.

Lithium ion batteries have been widely applied to many fields. However, the anode material in lithium ion batteries is mostly graphite, which has reached its highest capacity. Ten years ago, Distinguished Professor Chuan-Pu Liu of the Department of Materials Science and Engineering at NCKU developed Si technology to overcome current pulverization problems in replacement of graphite to reach a comparatively higher charge capacity. This allowed people to use their mobile phones and electric vehicles without having to constantly recharge.

Replacing graphite with different materials is a long-term goal that materials scientists all over the world are working toward. However, Liu has chosen to use the most difficult battery material.

Mass Production with Major Manufacturers

A silicon anode expands to three times its size when charging, and it contracts as it discharges. Therefore, the battery loses its effectiveness easily. After many years of hard work, Liu developed a production method that reduces the expansion, which improves the usability and durability of silicon anodes. Patents for this technology have been granted in Taiwan, the United States, and Mainland China. The collaboration with Wah Hong Industrial Corp., a TPEx listed company, has also been established to start mass production at their factory in Guantian District, Tainan.

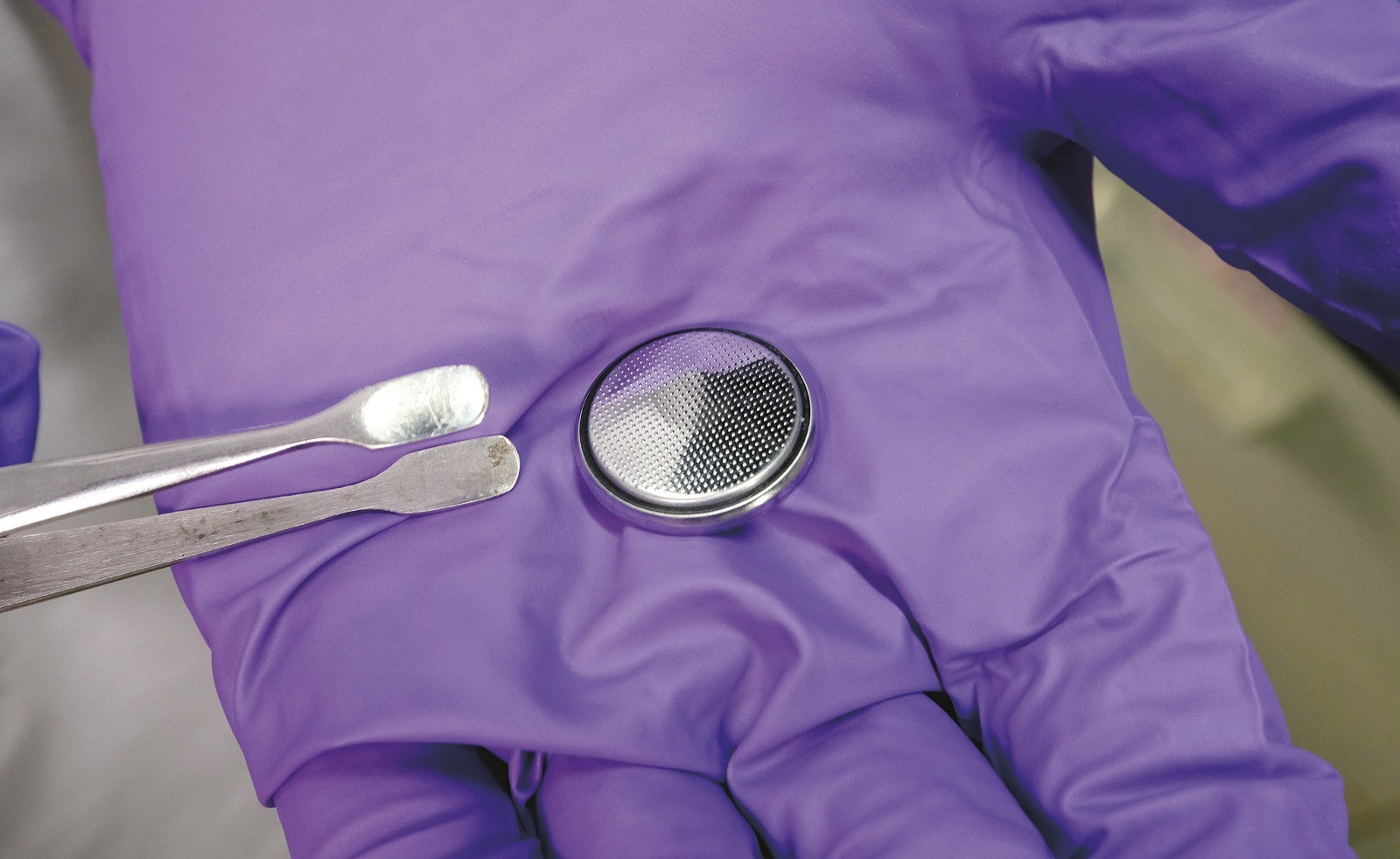

Solid-state batteries are also a major breakthrough made by Hi-GEM. This is the achievement of Hsi-Sheng Teng, Hi-GEM Associate Director and Department of Chemical Engineering Chair Professor, and his research team.

Liquid electrolytes are used for general batteries, which means that electrolyte solutions can leak when the casing is damaged. Furthermore, if the battery swells and ruptures due to overheating, it may trigger an explosion or other problems. On the other hand, solid-state batteries are very safe, but involve complicated production processes. Teng and his team overcame difficulties as they not only made the production process easier and more environmentally friendly, but also substantially reduced battery weight. This technology also involved many industry-academia collaborations with several companies.

Worldwide, solid-state batteries and high-capacity silicon-based electrodes both entail research that involves a great number of technologies. Both Teng and Liu mentioned that Taiwan’s market is not as big as that of the United States, China, and South Korea. “The only way we’ll have a chance to become a market leader is by choosing to do the most difficult thing.”